Identifying the Challenges in Traditional Labeling Processes

In the fast-paced world of manufacturing and packaging, efficiency and precision are critical. Traditional manual labeling processes often pose significant challenges, including:

- Inconsistencies and errors: Manual labeling is prone to human errors, leading to inconsistent label placement.

- Time-consuming tasks: Labeling by hand is a slow process, significantly impacting production speed.

- Labor-intensive processes: Manual labeling requires considerable manpower, increasing labor costs.

These issues ultimately affect production efficiency, causing delays and bottlenecks and raising concerns about quality control.

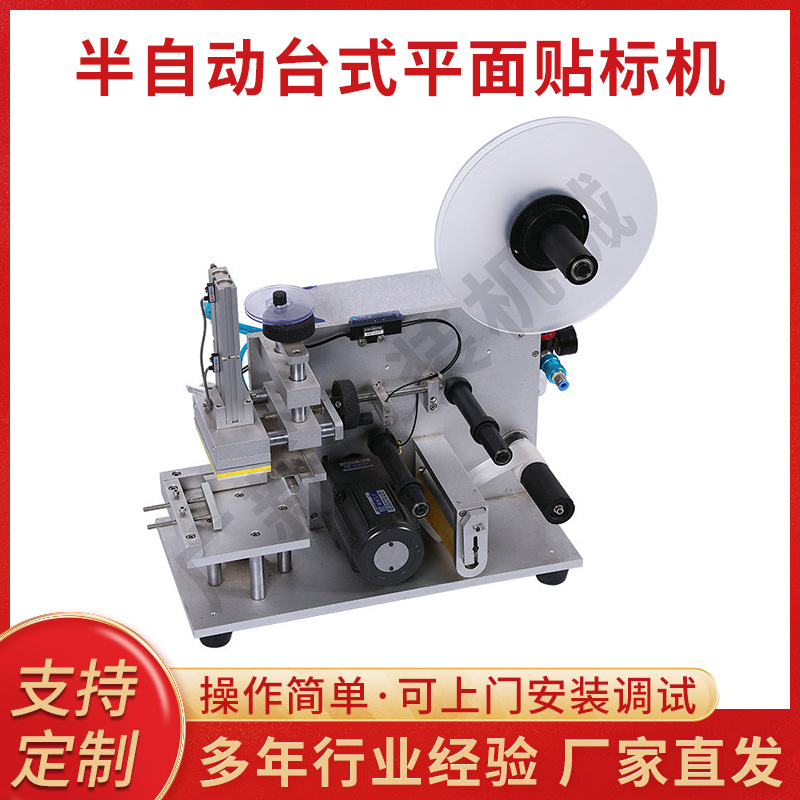

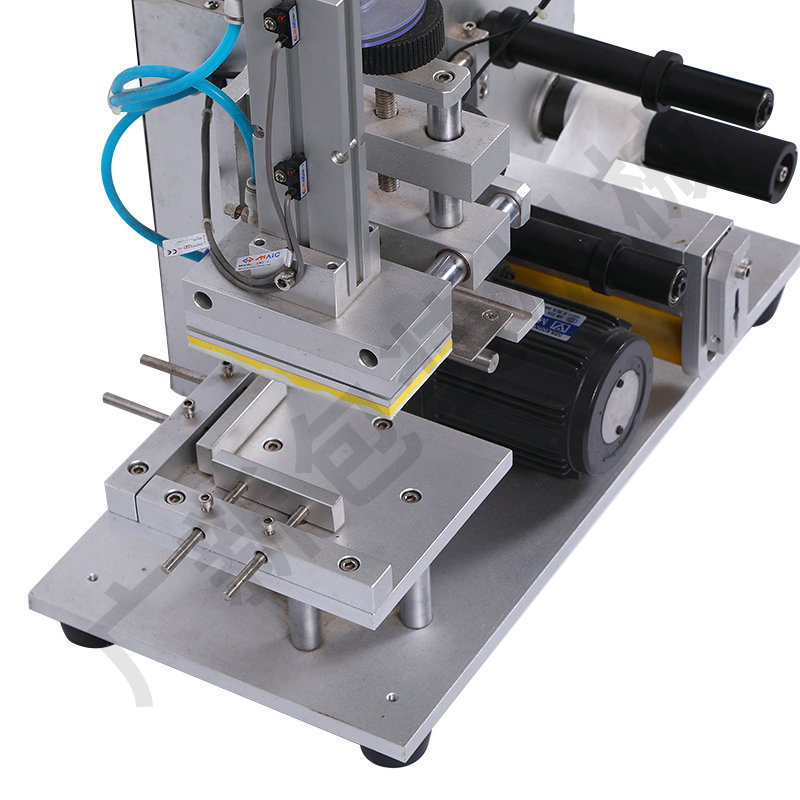

Features of the MT-60D Semi-Automatic Flat Labeling Machine

The MT-60D semi-automatic flat labeling machine addresses these challenges with its robust features:

Design and build quality

- Durable and robust construction: Built to last, ensuring long-term reliability.

- Compact footprint: Easily integrates into existing production lines without taking up much space.

Compatibility with various surfaces

- Ideal for flat and square surfaces: Perfect for labeling boxes, containers, and other flat items.

- Versatility in labeling different materials: Compatible with a wide range of materials, including plastic, glass, and metal.

Enhancing Precision and Speed

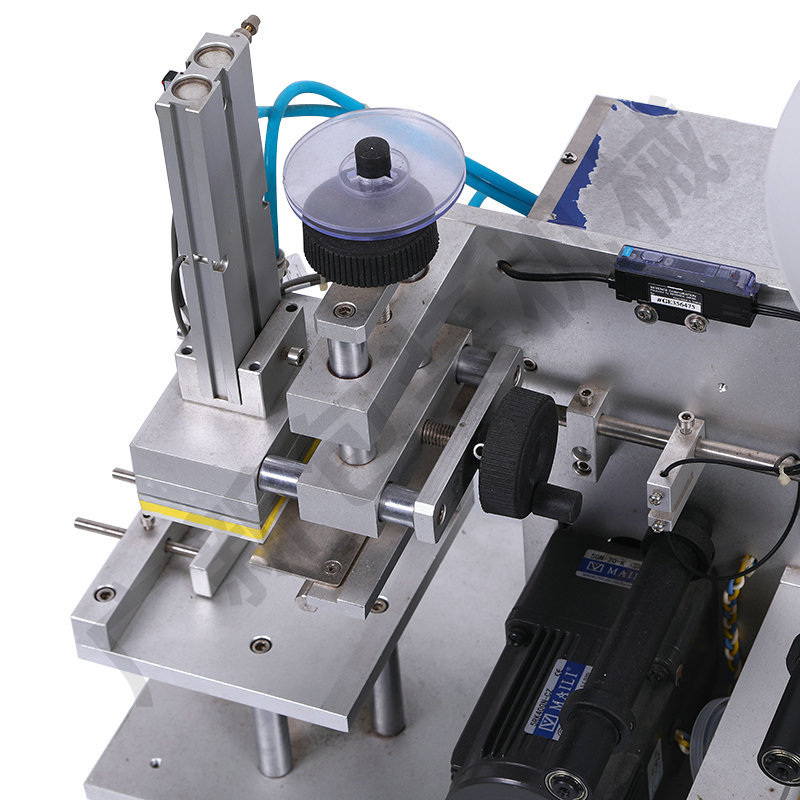

Advanced labeling technology

- High-precision sensors: Ensure accurate label placement every time.

- Consistent labeling: Minimizes errors, enhancing the overall quality of your products.

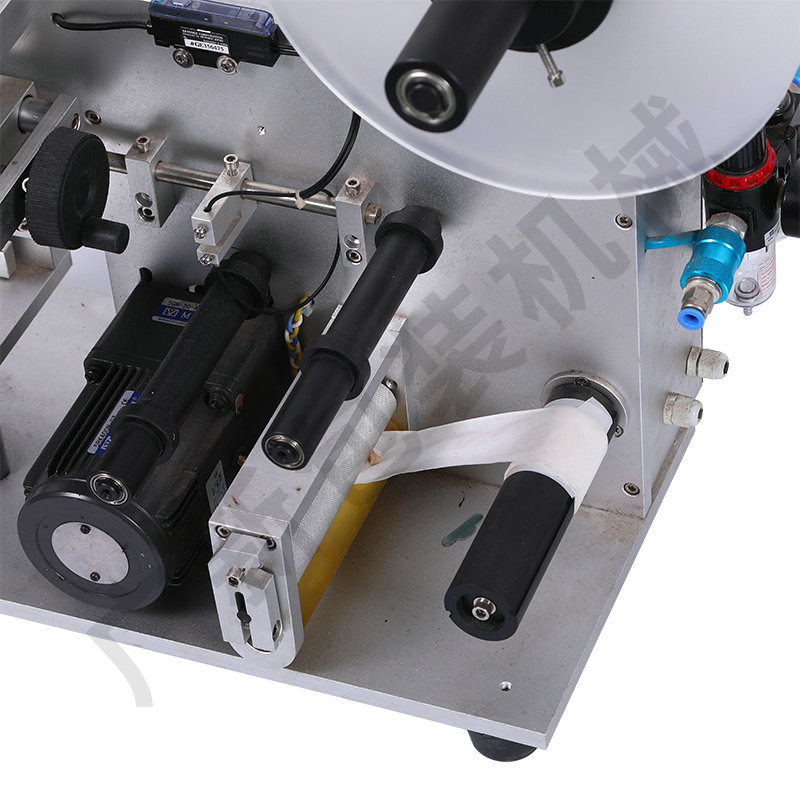

Speed improvements

- Increased output: Significantly faster than manual methods, boosting productivity.

- Efficient label application process: Streamlines labeling, reducing downtime.

User-Friendly Operation and Setup

Ease of use

- Intuitive controls and interface: Simple to operate, requiring minimal training.

Quick setup and adjustments

- Simple calibration: Easily adjustable for different label sizes.

- Fast changeovers: Quick switch between products, minimizing downtime.

Boosting Production Line Efficiency

- Streamlined workflow integration: Easily integrates into existing production lines, reducing interruptions.

- Reduction in downtime: Low maintenance needs ensure continuous operation.

- Improved quality control: Consistent label application enhances product presentation and brand image.

Cost-Effectiveness and ROI

Initial investment vs. long-term savings

- Reduction in labor costs: Less manual labor needed, saving on wages.

- Decreased waste and rework: High precision reduces errors, minimizing label waste.

Return on investment analysis

- Faster production times: Leads to increased output and quicker turnaround.

- Improved profitability: Higher efficiency translates to greater profit margins.

Real-World Applications and Case Studies

Examples of industries benefitting from the MT-60D

- Food and beverage: Ensures compliance with labeling regulations and enhances product appeal.

- Pharmaceuticals: Accurate labeling for safety and regulatory compliance.

- Cosmetics and personal care products: Professional labeling for a premium brand image.

Success stories

"The MT-60D has revolutionized our production line. We've seen a 30% increase in output and significantly reduced labeling errors." - A Satisfied Customer

"Thanks to the MT-60D, our labeling process is now faster and more accurate, leading to higher customer satisfaction." - Another Happy Client

Maintenance and Support

Routine maintenance tips

- Regular cleaning and inspection: Keeps the machine in top working condition.

- Replacement parts: Easily available for minimal downtime.

Access to customer support

- Technical assistance: Available for troubleshooting and maintenance.

- Training resources: Comprehensive user manuals and training materials provided.

Future-Proofing Your Labeling Process

Scalability and adaptability

- Accommodating future growth: Designed to handle increased production volumes.

- Integration with other automated systems: Easily integrates with other machinery for a fully automated line.

Staying ahead of industry trends

- Technological advancements: Regular updates to keep up with the latest technology.

- Adapting to market demands and regulations: Ensures compliance with evolving industry standards.

Conclusion

The MT-60D Semi-Automatic Flat Labeling Machine offers a comprehensive solution to streamline your labeling process. With enhanced efficiency, precision, and cost savings, it is an invaluable addition to any production line.

Consider the MT-60D for your labeling needs. For further inquiries, demonstrations, or quotes, please contact us at Yiwu Guangxin Packaging Machinery Firm. We're here to help you enhance your production efficiency and product quality.